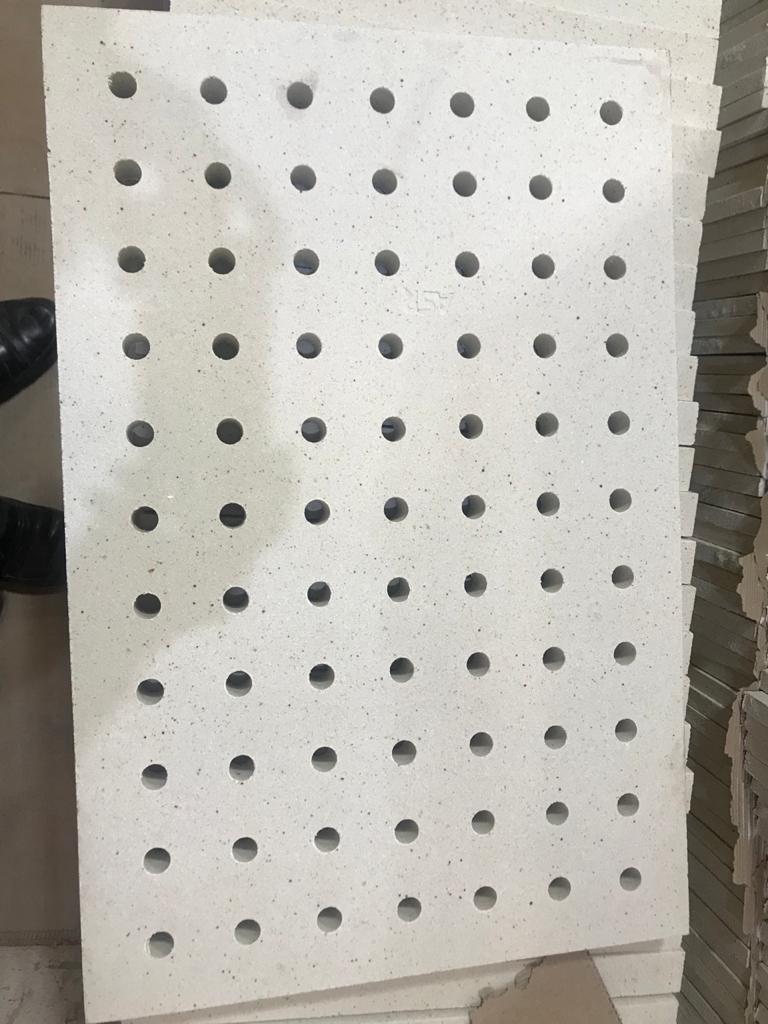

Kiln Furniture

Product Details:

Product Description

Kiln Furniture

Refractory products used by the ceramics industry to support wares during firing are generally referred to as kiln furniture. The rigorous conditions encountered in this application demand a material that resists deformation or mechanical failure during repeated heating and cooling cycles.

Kiln furniture pieces are damaged by cracking, bending, the accumulation of dirt and glaze or surface degradation due to oxidation or some other form of chemical attack or contamination.

For service temperatures up to 1300 deg C the most popular type of refractory material contains the mineral cordierite, a magnesium aluminum silicate with a very low thermal expansion coefficient, rendering it highly resistant to thermal shock. Most commercial cordierite kiln furniture bodies are formulated to produce about 50% cordierite, the remainder comprising mullite (Molochite-based or chamotte-based) and amorphous material.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 24AAZFA6595M1ZG

|

AMERYS SPECIAL REFRACTORY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |